Product Manual

1.Product categories: optical window, optical lens, optical prism, optical dome, sapphire hemispherical, dichroic mirror, beam splitter mirror, glass aspherical lens, free-form lens,Irregular lens

2.Processing Materials: zinc selenide, zinc sulfide, quartz, sapphire, calcium fluoride, magnesium fluoride, barium fluoride, lithium fluoride, germanium, silicon, ZF glass, K 9, NBK7 and other visible, infrared, ultraviolet materials.

3. Size: D1-D500

4. Machining accuracy:

(1) Angle: 2'

(2)Parallelism: 2'

(3)PV:1/40,RMS:1/100

(4)Finish: 40/2020/1010/5

(5) Center Deviation: 10'

(6)diameter/thickness, tolerance: ± 0.01

5.coating:Custom-made according to customer requirements.

Email:

junbang.optical@gmail.comPhone:

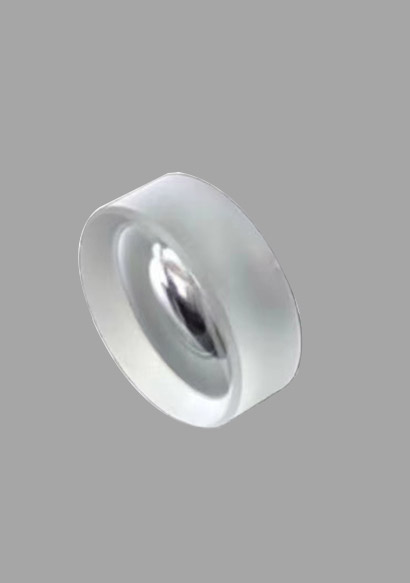

+86-18171082907Spherical single lens

For simple applications, standard planar convex, concave, biconvex, and biconvex lenses are sufficient. For better performance, the exterior lens is optimized to reduce aberrations while still maintaining the spherical surface. More performance improvements can be achieved by using multiple lens elements in a composite optical system. These multi-element optical systems usually use crescent lenses, although they are rarely used alone. For demanding applications, spherical single lenses will not perform as well as achromatic lens (for broadband and monochromatic light sources) or spherical lenses (for monochromatic light sources) . For more information about other types of lenses, see the labels for achromatic lens and aspherical lenses.

Standard single lens

A variety of basic single lens designs: planar convex lens, biconvex lens, planar concave lens, and biconvex lens. Each of these lenses is suitable for different applications. Convex and biconvex lenses are positive lenses (that is, they have a positive focal length) that focus collimating light into focus, while concave and biconvex lenses are negative lenses that cause collimating light to diverge. The shape of each lens minimizes aberrations based on a certain conjugate ratio, which is defined as the ratio of object distance to image distance (called the conjugate distance) .

Positive Lens:

Flat convex lens

A plane convex lens is suitable for cases where one conjugate distance is more than five times that of another. The performance of this lens shape is suitable for the case of infinite conjugation ratio (focusing collimation or point source collimation) .

Double convex lens

A biconvex lens is suitable for cases where one conjugate distance is 0.2 to 5 times that of another. The performance of this lens shape is suitable for cases where the object distance and the image distance are the same.

Negative Lens:

Flat concave lens

A plane concave lens is suitable for cases where one conjugate distance is more than five times that of another. They introduce a negative spherical aberration, which can be used to balance the spherical aberration introduced by a single lens with a positive focal length.

Double concave lens

A double concave lens has a negative focal length and is usually used to increase the divergence of the focused light.

Reduced

Aberrations. In order to minimize spherical aberrations, the lens should be positioned so that the curvature side is closer to the common principal point. For convex and concave lenses with an infinite matching ratio, this means that the surface should face the collimated beam (shown above) . The number of lenses, defined as the focal length divided by the aperture diameter, has a significant effect on the degree of aberration. Smaller lenses (“Fast” lenses) introduce more aberrations than larger lenses (“Slow” lenses) . When the lens shape is below F10 or so, the lens shape becomes very important and should be considered as an alternative to spherical single lenses and other lenses below F2(such as achromatic lens and aspherical lenses) .

Appearance Lens

The shape lens is designed to minimize spherical and comet aberrations (caused by light that is not on the optical axis) while still using the sphere to form the lens. It is easier to manufacture an external lens (as described on the aspheric lens label) with a spherical design than with an aspheric lens, thus reducing costs. Each side of the outer lens is polished and has different radius of curvature, providing better performance for spherical single lens. For small-diameter input beams, the outer lens even has diffraction properties. These lenses are commonly used in high power applications where achromatic glue lenses can not be used.

Curved moon lens and multi-element lens system

Moonlight lenses are commonly used in multi-element optical systems to modify the focal length without introducing significant spherical aberrations. The optical performance of a multi-element lens system is usually significantly better than that of a single lens. In these systems, the aberration introduced by one element can be corrected by subsequent optical elements. These lenses have convex and concave surfaces and can be positive or negative lenses.

The company's Optical Lens are widely used in a variety of fields, including: optical instruments: Optical Lens used to manufacture a variety of optical instruments, such as telescopes, microscopes, cameras, spectrometers and so on. They help control and focus light to get clearer images and more accurate data.

Laser: Optical Lens are also used to make lasers, which use special optical elements to generate, control, and focus laser beams. Optical Communication: optical lens is an indispensable component in optical communication. They are used to make fiber optic connectors, optical amplifiers, optical modulators and so on.

Medical Equipment: Optical Lens are also used in medical equipment, such as eyeglasses, magnifying glasses, microscopes, surgical lasers and so on.

They can help doctors make more accurate diagnoses and treatments. Other fields: Optical Lens are also used in mechanical manufacturing, optical metrology, aerospace and other fields, as well as many daily necessities, such as cameras, telescopes, microscopes, magnifiers and so on.

| Material | according to customer requirements |

| Design wavelength | Customized |

| Diameter error | + 0.01/-0.01 mm |

| Center thickness error | + 0.01 mm |

| Irregular shape | wavelength/4@632.8 nm |

| Focal length error | ± 2% |

| Lens alignment error | 1 min |

| Surface smoothness | 2-3 |

| Chamfer | 0.2 mm x 45 ° |

| Ravg | < 0.5%@250-400 nm |