In the past, the classical polishing technique was used for aspherical mirror, that is, the spherical surface which is closest to the aspherical surface is first developed by single/multi-axis machine, then the local polishing and polishing is done according to the design, there is a greater blindness, and low efficiency, can not guarantee the stability of the processing. To this end, scientists combined computer technology, automatic control technology, basic theory of elasticity, etc. , developed a variety of surface polishing technology, including computer-controlled small grinding head processing technology and, controllable flexible optical polishing technology, such as jet polishing, ion beam polishing, magnetorheological polishing, stress disc polishing, etc. .

01 computer-controlled small grinding head machining technology (CCOS)

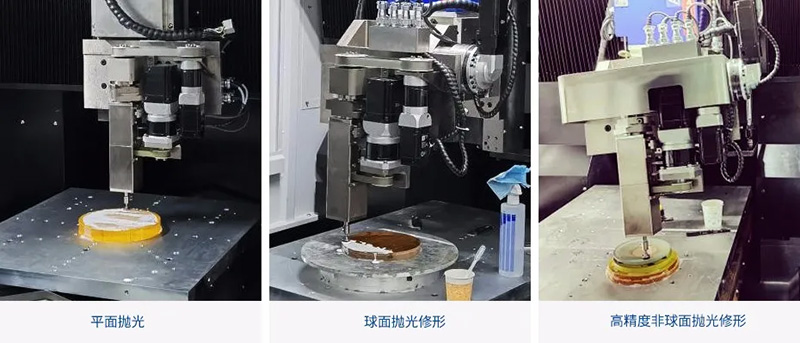

The polishing technology of computer-controlled small grinding head is an advanced technology combining traditional polishing experience with modern numerical control technology, now it has gradually replaced the traditional polishing technology to become the mainstream of aspheric mirror processing technology in our country. In actual processing, the data of the surface topography of the target workpiece can be input into the control system ahead of time, according to the specific polishing environment, by controlling the main factors such as tool head residence time, velocity, polishing track, polishing pressure, and the secondary conditions such as PH value and concentration of polishing fluid, tool attitude angle and temperature, and repeatedly detection, processing, so that the optical performance of the surface accuracy and the surface accuracy of the error continues to reduce, and finally achieve the target surface accuracy.

Compared with the classical polishing technology, CCOS is a deterministic machining method, which can simulate the polishing process of the whole optical surface as far as possible, thus achieving higher machining accuracy. However, due to the small tool head, there is also a problem of low machining efficiency for polishing CCOS with large aspheric mirror. In addition, the polishing and dumping plate will wear with the increase of working hours, which leads to the removal function can not maintain long-term stability, and also has some impact on the accuracy.

02 stress plate polishing technology

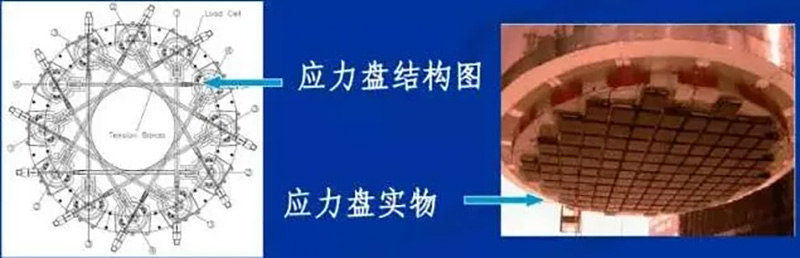

In order to improve the efficiency of small grinding head in aspheric optical elements processing, larger size grinding head is usually selected to achieve high removal. However, because the larger diameter of the disc and the aspheric optical elements do not fit well, resulting in high-precision machining can not be completed. To solve this problem, the scientists put their eyes on the optimization of the grinding head (polishing disc) , developed a stress disc polishing technology.

The polishing technology of stress disc is the technology that carries on the dynamic deformation to the polishing disc and then carries on the polishing to the work piece, specifically is in the dynamic grinding polishing process of the stress disc radial translation and the rotation, the real-time control of the stress disc by the computer, the dynamic deformation of the disc is made to match the theoretical surface of the aspherical surface, so that the disc and the aspherical surface can fit together and the material can be removed more stably in the process of the active disc machining.

Compared with CCOS technology, the stress disc polishing technology has higher machining efficiency, and can remove the surface height first, correct the high frequency error effect of the smooth local, it can make the ground mirror naturally smooth in a wide range of spatial frequencies, and is very suitable for the processing of large-aperture optical aspherical surfaces, at present, it is one of the main technologies to realize high-efficient and high-precision machining of 2M, 4m and even 8m primary mirror. However, due to the need to adjust the drive to change the bending moment, torque so that the stress plate and workpiece surface always fit, control is more complex.